Our Services

Explore a comprehensive range of services tailored to your electric vehicle and energy storage system needs, including advanced engineering design, seamless integration assembly, and meticulous testing and qualification. Entrust us with your journey as we provide unwavering support, ensuring reliability and compliance every step of the way.

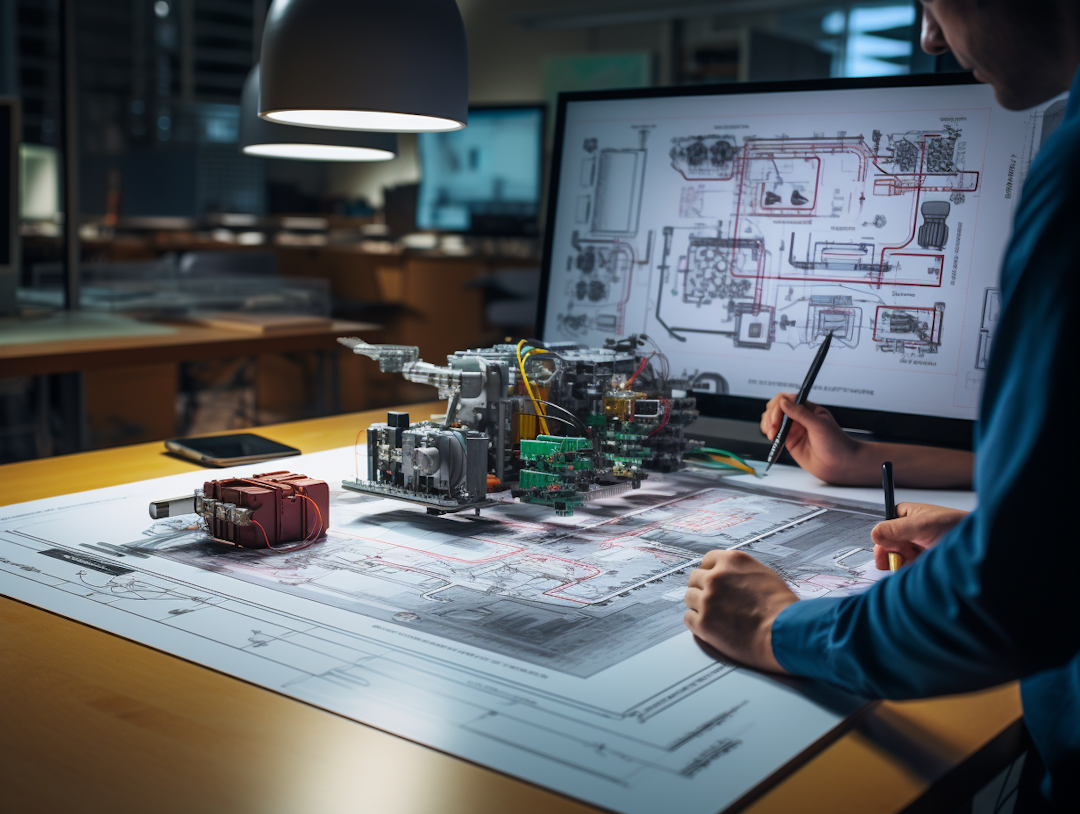

Engineering Design

Battery Design

Crafting the architecture of battery packs to enhance performance, safety and energy density. Engineering modular frameworks for effortless scalability and assimilation into diverse applications.

Cell Procurement and Acquisition

Providing recommendations on the choice of suitable batteries or fuel cell stacks according to performance, cost, and application specifications. Forging alliances with esteemed cell producers and suppliers to guarantee excellence and dependability.

Immerse yourself in a realm where precision intertwines with innovation, where each battery and fuel cell narrates a story of perfection.

Integration Assembly

Electrical Integration

Incorporating batteries or fuel cells into electrical subsystems, including power management systems, inverters, converters, and control electronics. Developing wiring assemblies, connectors, and interconnections to enable smooth electrical linkage and communication among components.

Control System Integration

Integrating control systems and algorithms to manage the operation of batteries or fuel cells, including state-of-charge estimation, voltage regulation, and power distribution. Implementing communication protocols to enable real-time monitoring and control of system parameters.

Our premier sustainable solutions empower systems and spearhead groundbreaking innovations in electric vehicle technology, laying the groundwork for a more environmentally conscious tomorrow.

Compliance

Assessment and Environmental Sustainability

Performing comprehensive analyses to assess the ecological footprint and sustainability of batteries and fuel cells from raw material extraction to disposal. Recognizing avenues for conserving resources, recycling, and repurposing to mitigate environmental impact and advocate for sustainability.

Quality Management Systems

Setting up and upholding quality management frameworks adhering to global benchmarks like ISO 9001, ensuring uniform product excellence and customer contentment. Executing internal evaluations and quality appraisals to track adherence to QMF criteria and pinpoint avenues for ongoing enhancement.

Empower your systems with reusable batteries and fuel cells, laying the foundation for groundbreaking space missions.

Testing

Modeling and Simulation

Harnessing computational modeling and simulation tools to forecast the electrochemical dynamics and performance attributes of batteries and fuel cells. Conducting evaluations of cell deterioration, capacity degradation, and effectiveness across varied operational scenarios to refine design variables.

Testing and Validation

Conducting integration testing and validation to ensure the functionality, performance, and safety of the integrated system. Performing functional testing, durability testing, and environmental testing to verify compliance with specifications and standards.

Empower your operations with rigorous testing, ensuring operational excellence beyond the atmosphere.

Qualification

Prototype Qualification

Qualifying prototypes of battery packs or fuel cell systems through rigorous testing and validation to demonstrate performance, reliability, and safety. Conducting functional testing, environmental testing, and reliability testing under simulated operating conditions to identify potential issues and validate design assumptions.

Manufacturing Process Qualification

Qualifying manufacturing processes and procedures used in the production of batteries and fuel cells to ensure consistency, and quality. Conducting process validation studies, equipment qualification, and process capability analysis to verify compliance with quality standards and regulatory requirements

Unleashing ingenuity through sustainable batteries and refined fuel cells for pioneering aerospace industry.

Reliability

Failure Analysis and Root Cause Investigation

Investigating product failures and malfunctions to determine the root cause and contributing factors using techniques such as microscopy, spectroscopy, and thermal analysis. Identifying design flaws, material defects, manufacturing errors, and external factors that may affect reliability and performance.

Design for Reliability (DFR)

Integrating reliability considerations into the product design phase to enhance robustness, fault tolerance, and resilience to environmental stressors and operating conditions. Conducting reliability-focused design reviews and failure mode effects analysis to identify and mitigate potential failure modes and weaknesses in the design.

Propel your systems forward with our sustainable batteries and reusable fuel cells.

| NAICS Code | Industry |

|---|---|

| 335910 | Battery Manufacturing |

| 333998 | All Other Miscellaneous General Purpose Machinery Manufacturing |

| 335999 | All Other Miscellaneous Electrical Equipment And Component Manufacturing |

| 541713 | Research and Development in Nanotechnology |

| 334516 | Analytical Laboratory Instrument Manufacturing |

| 333618 | Other Engine Equipment Manufacturing |

| 541690 | Other Scientific and Technical Consulting Services |

| 541715 | Research and Development in the Physical, Engineering, and Life Sciences (except Nanotechnology and Biotechnology) |